| After a very disappointing 1968 season blowing up the bottom ends of the Tunnel Port 302 engines, Ford designed a new engine specifically for F.I.A. Trans Am competition in 1969, the Boss 302. Introduced April 17, 1969, about 8,600 were built. | |

1970 Mustang Boss 302 |

|

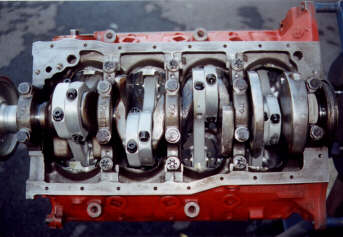

| The block is essentially the next generation of 289 HP hardware, but features a forged steel crankshaft, 4-bolt main caps, and screw-in freeze plugs. These modifications were developed as part of the 302 Tunnel Port design. Street versions used connecting rods similar to the 289 HP while the Trans Am version used heavier 7/16" bolts. |

|

The real magic of the Boss engines

comes from the canted-valve Cleveland cylinder heads. While the Boss 302

is normally considered a 302 with Cleveland heads,

these canted-valve heads were used first on the Boss before

the rest of the Cleveland was developed.

As fitted to the Boss, the heads feature steel spring seats,

screw-in rocker studs, pushrod guide plates, and adjustable

rocker arms.

The Boss 302 and 351C-4V head casting are the same except for a minor difference

in water passages. Camshafts were quite similar to the 289 HP.

Due to the larger Cleveland-style heads, the Boss 302 weighs somewhat more

than the normal 302, tipping the scales at 500 lbs.

The street version was conservatively rated at 290 HP @ 5800 RPM. During the '69 Trans Am season the racing engines were producing 470 bhp with a 9,000 rpm redline. |

|

|

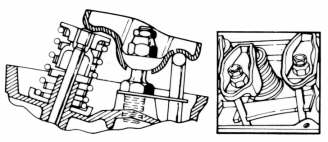

| Designed for the road racing environment, the engines featured a scraper style windage tray. This tray attached to four special main cap bolts with small threaded holes in their heads. | |

|

Boss 302 bottom end. D1ZE service block and aluminum rods. The 4-bolt caps can be seen here. |

|

Oops! Even the strong stuff can be blown up if you try hard enough. |